How to Select and Verify Quality & Certifications for Egg Liquid Products: A Practical Guide for Global Buyers

Navigating the global supply chain for Egg Liquid Products requires more than just comparing prices. For food manufacturers, bakeries, and ingredient suppliers, ensuring consistent quality, safety, and compliance is paramount. This guide provides a step-by-step framework for evaluating and verifying the credentials of your Pasteurized Egg Liquid or Egg Powder supplier, using industry-leading practices and real-world examples.

Step 1: Understand the Critical Quality Parameters for Egg Liquid Products

Before diving into certificates, you must know what defines quality in Egg Liquid Products. Key parameters vary by product type:

- For Pasteurized Egg Liquid: Look for specifications on microbial counts (Salmonella, E. coli), pasteurization temperature/time validation, viscosity, and color. A reliable supplier like Jiangsu Tiancheng Egg Industry Co., Ltd. uses MOBA (Netherlands) automated systems to ensure precise control.

- For Frozen Egg Liquid: Thawing stability, crystal formation size, and functional property retention (foaming, emulsification) post-thaw are crucial.

- For Specialized Products like Heat Stable Egg Liquid or Heat Stable Egg Yolk Powder: Verify the heat-treatment methodology and performance data in target applications (e.g., retort processing, UHT).

- For Egg Powders (Whole Egg Powder, Egg White Powder, Egg Yolk Powder): Key specs include solubility index, moisture content, bulk density, and functional performance in reconstitution.

Always request a detailed Certificate of Analysis (CoA) for each batch. Reputable suppliers will provide this readily.

Advanced storage and control systems, like those at Tiancheng's facility, are essential for maintaining the quality of liquid egg products from processing to storage.

Step 2: Decipher the Certification Landscape – What Each Logo Means for Your Business

Certifications are your objective proof of a supplier's commitment to systematic quality and safety management. Here’s what to look for:

Core Food Safety & Quality Certifications:

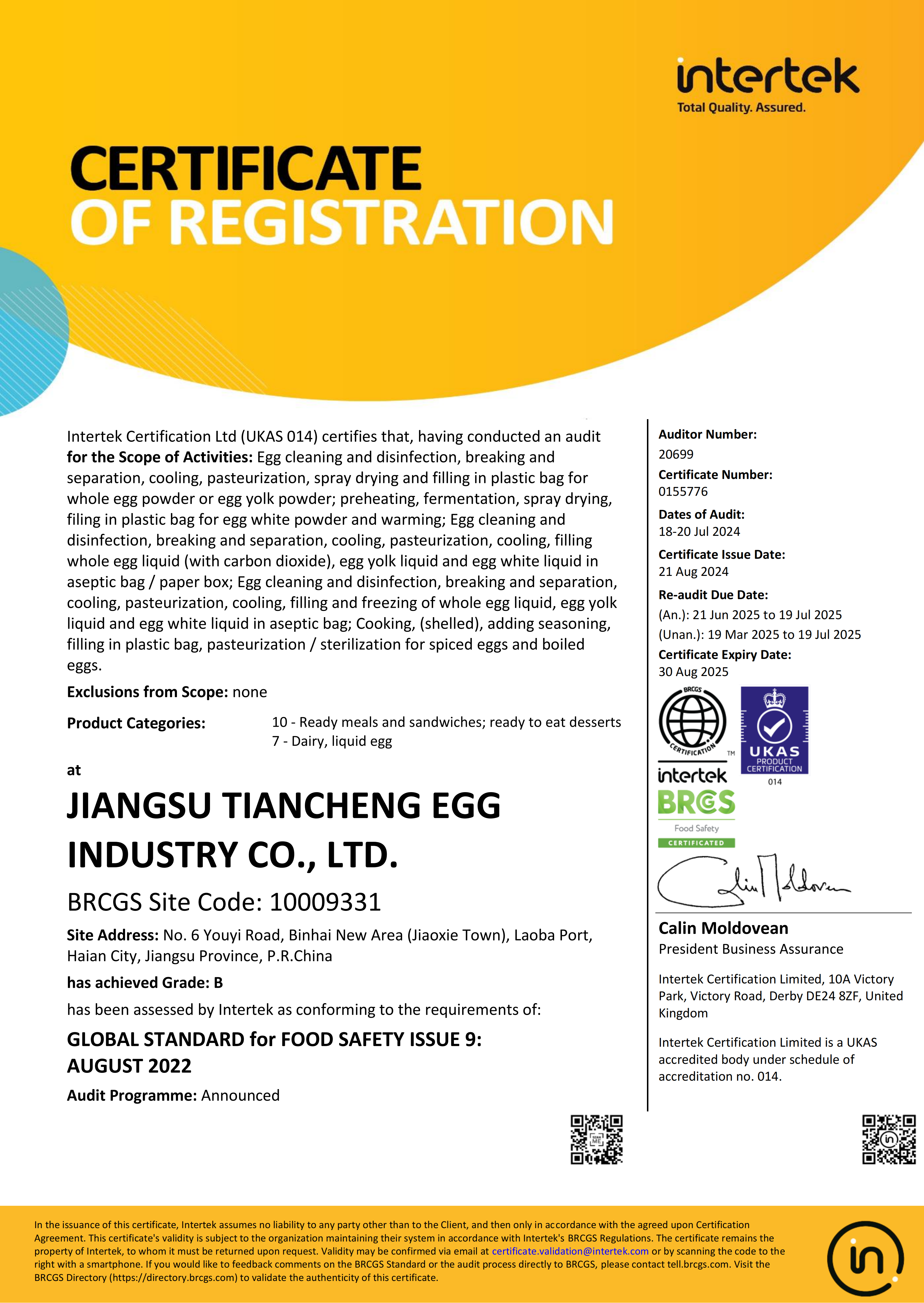

- FSSC 22000, SQF, or BRCGS: These are GFSI-benchmarked (Global Food Safety Initiative) standards and are considered the gold standard for food safety. They cover hazard analysis, prerequisite programs, and management systems. A supplier holding one of these, like Jiangsu Tiancheng Egg Industry which holds both SQF and BRCGS certificates, demonstrates a world-class, audited food safety system.

- ISO 9001 (Quality Management) & ISO 14001 (Environmental Management): ISO 9001 ensures consistent quality in processes, while ISO 14001 shows environmental responsibility. Together, they indicate a mature, process-oriented company.

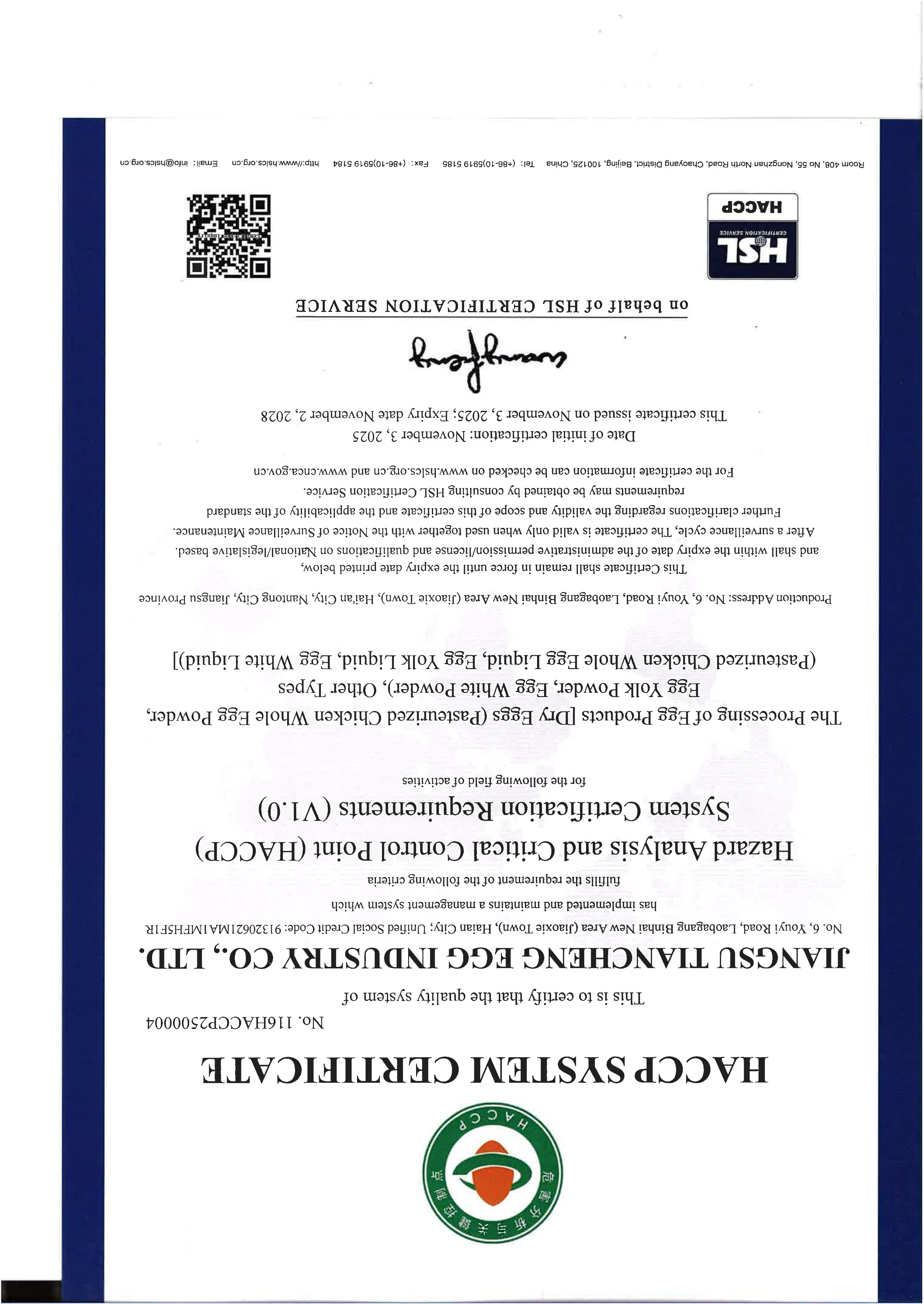

- HACCP: The foundational hazard analysis system. It should be a given for any serious supplier.

Market-Specific & Religious Certifications:

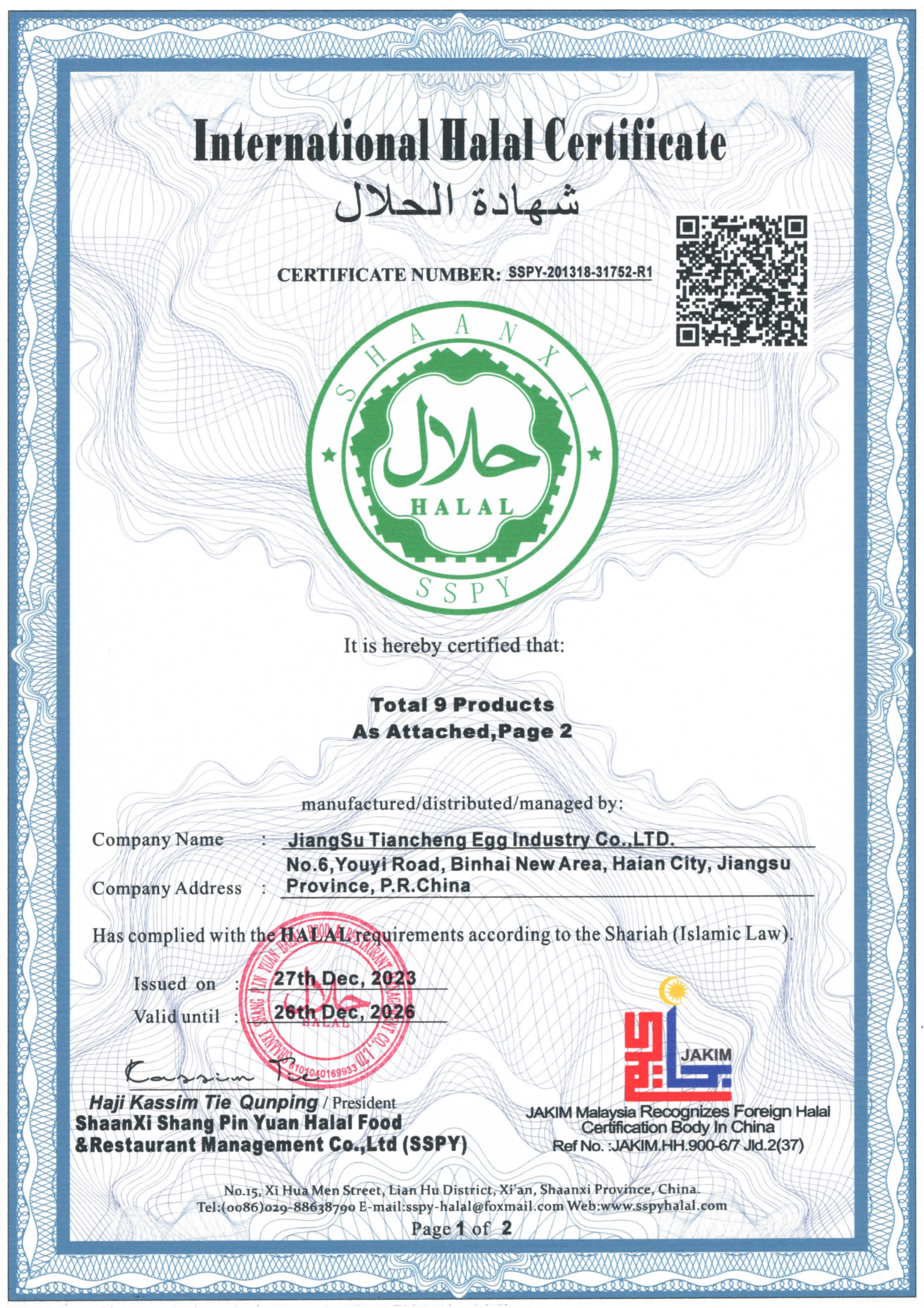

- Halal Certification: Essential for accessing Muslim-majority markets. Verify the issuing body's recognition. Tiancheng holds a recognized Halal certificate.

- EU Market Approval: For exporting to Europe, the supplier's establishment must be approved by Chinese authorities (GACC) and listed by the EU. Confirm the supplier's EU approval status directly.

Step 3: Investigate the Source – Traceability is Key

The quality of Egg Liquid Products begins at the farm. A vertically integrated model is a significant advantage.

- Ask: "Where do your eggs come from?" The ideal answer involves company-owned or strictly controlled farms.

- Case in Point: Jiangsu Tiancheng Egg Industry sources raw eggs from its parent group's modern, intelligent farm with 5 million laying hens. This allows for complete control over feed, animal welfare, and biosecurity, creating a traceable and consistent raw material supply—a critical factor for producing safe Salted Egg Liquid, Sugared Egg Liquid, or standard Pasteurized Egg Liquid.

Step 4: Assess Technological Capability and Innovation

Certificates prove systems, but technology enables quality. Evaluate the supplier's processing equipment and R&D capability.

- Processing Equipment: State-of-the-art equipment minimizes contamination and preserves functionality. For example, fully automated liquid egg processing lines from MOBA (Netherlands), as used by Tiancheng, represent top-tier technology.

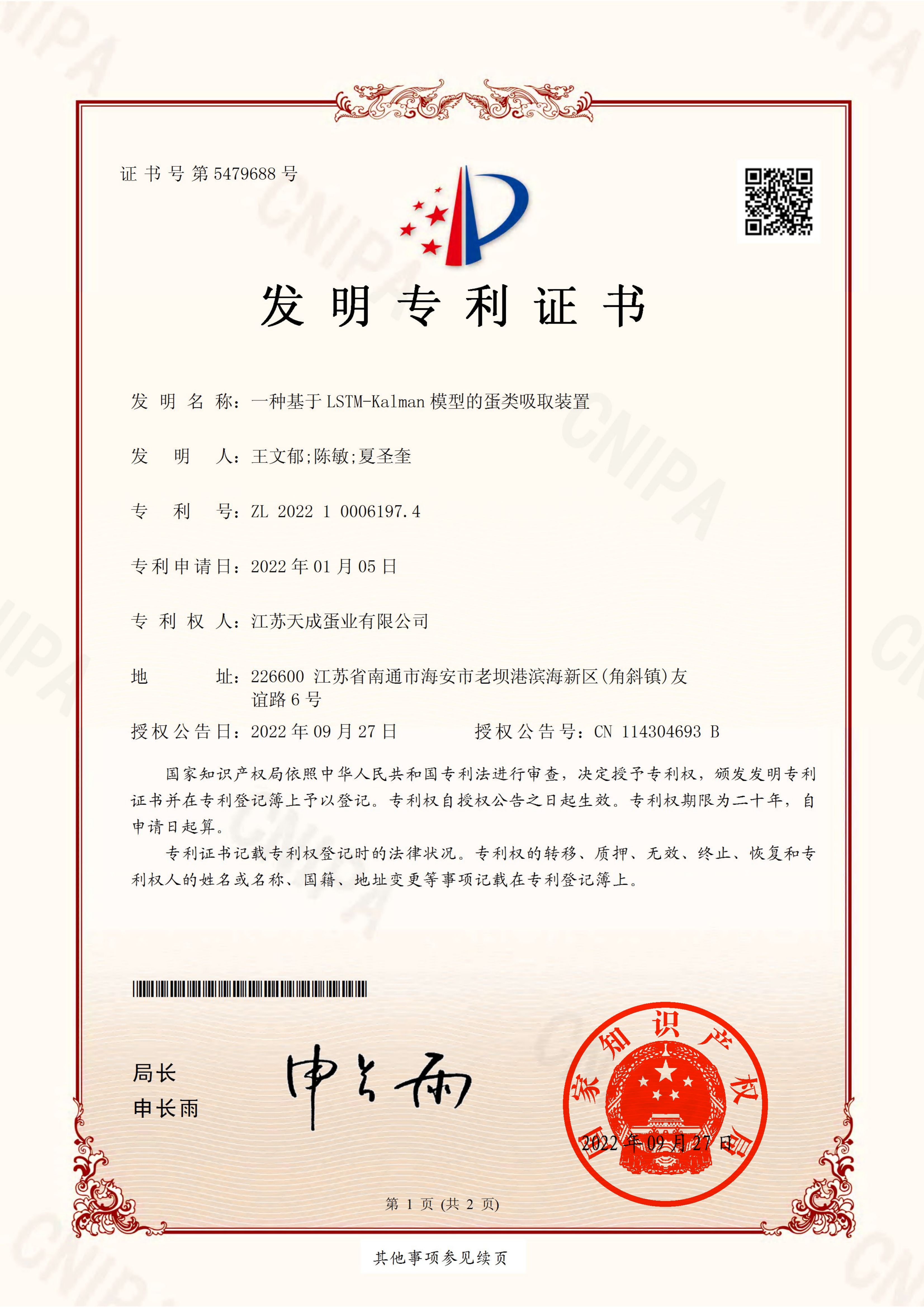

- Patents and R&D: Look for invention patents related to egg processing. They indicate a commitment to solving industry problems and innovating. Tiancheng holds patents for specialized equipment, such as an "egg white lysozyme extraction device," showcasing technical depth beyond basic processing.

- Product Range: A supplier offering a wide range, from basic Whole Egg Powder to specialized Heat Stable Egg Yolk Powder and Eggshell Membrane, demonstrates application knowledge and flexible production capabilities.

Step 5: Validate Through Reference Checks and Audits

Due diligence is not complete without external validation.

- Client Portfolio: A supplier serving global blue-chip companies (e.g., Mondelēz, Nestlé, Ajinomoto) has already passed rigorous qualification audits. This serves as a powerful reference.

- Request Audit Reports: While full reports are confidential, suppliers can often share summary findings or attestations from recent third-party audits (SQF, BRC).

- Consider a Site Audit: If volume justifies it, visiting the factory is invaluable. Inspect the laboratory, hygiene practices, and ask to see certificate originals. Check the aseptic filling machine and pasteurization system in operation.

Step 6: Build a Partnership, Not Just a Transaction

Your chosen supplier should be a partner in your product development. Discuss their technical support, customization options for products like Frozen Egg Liquid or Egg White Powder, and their responsiveness to quality inquiries.

Jiangsu Tiancheng Egg Industry Co., Ltd., with its comprehensive certification portfolio (SQF, BRC, ISO9001, ISO14001, HACCP, Halal), vertical integration, and advanced Dutch technology, exemplifies a supplier that can meet these rigorous criteria. Their annual capacity of 36,000 tons of egg liquid and 1,800 tons of egg powder ensures scalable supply for global partners.

Final Checklist for Your Next Supplier Evaluation:

- ✅ Obtain and review batch-specific CoA for your target product (Egg Yolk Liquid, Whole Egg Powder, etc.).

- ✅ Verify valid certificates: At least one GFSI standard (SQF/BRC), ISO 9001, HACCP, and market-specific certs (e.g., Halal).

- ✅ Confirm raw egg source and traceability system.

- ✅ Evaluate processing technology and innovation (patents, specialized lines).

- ✅ Check references and client list.

- ✅ Discuss technical support and customization capabilities.

By following this structured "how-to" approach, you can move beyond price-based decisions and select a Egg Liquid Products supplier that guarantees safety, quality, and reliability, ultimately protecting your brand and ensuring the success of your food products.

For more information on certified egg ingredients, contact:

Jiangsu Tiancheng Egg Industry Co., Ltd.

Contact: Mr. Hu | Phone: +86 15706273311 | WhatsApp: +86 18020359920

Email: jstc@tcgrp.cn | Websites: www.tcegg.cn, www.tcegggroup.com

Address: No. 29, Changjiang East Road, Hai'an City, Nantong, Jiangsu, China.